Troubleshooting MUST start out simple. Basic troubleshooting of common problem areas provides a good starting point, but simple things should not be overlooked; battery charge, corroded or loose battery terminals and interlocks not satisfied. The most common cause of an electrical failure is an OPEN CIRCUIT; this can be in wiring, switches, connectors or other components. When you swapped that sensor, controller, VSM/ECU or control card and the truck ran, was the component really faulty or did you just refresh a bad connection causing the issue?

Your senses and experience are your best assets in solving problems in an efficient manner. Look, Listen, Touch and Smell.

- Visual evidence of conditions that could result in faults.

- Are there any unusual noises or vibrations?

- Are there odors or other evidence of fault conditions?

Proper troubleshooting takes time. Don’t rush, it takes more time to do it right a second time!

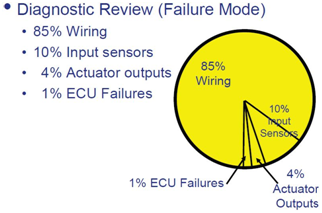

A diagnostic review studied thousands of repairs and warranty claims to determine the actual failure mode of electrical incidents and these are the results of the study. This can be applied to ICE as well as electric powered trucks.

In practical terms, if you have 100 service

calls for electrical issues in a month:

85 will be a wire, terminal, pin or socket

10 will be a TPS, O2, MAP or speed sensor

4 will be an injector, solenoid or valve coil

1 will be an ECU, VSM or other controller

Troubleshooting Do’s

- Familiarize yourself with truck operation

- Check the fault log history, the first fault may have caused subsequent faults

- Write down codes and erase them, operate truck and see if they return

- Check the basic items; battery volts/gravity/condition, fuel and other fluid levels

- Always follow the code procedures in order, don’t skip troubleshooting steps

- Use the proper tools; onboard diagnostics, DMM, PC Service Tool or fuel system software

- Use a back probe tool or appropriate pin over DMM probe to back probe connectors

Troubleshooting Don’ts

- Do not assume that with integrated diagnostics you won’t need basic troubleshooting skills

- Do not assume ANYTHING if you are unfamiliar with basic truck systems or operation

- Do not immediately assume that the VSM, ECU, Controller or other major component is faulty

- Do not use a test light unless a manual procedure specifically calls for it

- Do not poke holes in, slice/strip insulation or damage control wires for troubleshooting

- Do not jam DMM leads inside connector sockets or pins, use proper back probe tools

- Do not throw parts at a problem trying to fix it, be a troubleshooter and find the root cause