The table below provides detailed information on the symptoms of leaf chain wear, the probable causes and the corrective measures that should be taken.

| Symptom | Appearance | Probable cause | Correction |

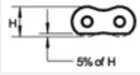

| Worn contour |  | Normal wear on sheave Abnormal wear rubbing on guides | Replace leaf chain when 5% worn Check Leaf chain alignment or increase clearance |

| Worn surfaces on outer plates or pin heads |  | Misalignment, rubbing on side flanges | Check leaf chain alignment and correct clearance as necessary |

| Tight joints |  | Dirt or foreign substance packed in joints or corrosion or rust or bent pins | Clean & re-lubricate leaf chain Replace leaf chain |

| Missing parts |  | Missing at original assembly | Replace leaf chain |

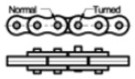

| Abnormal protrusion or turned pins |  | Excessive internal friction caused by high loading and inadequate lubrication | Replace leaf chain, improve lubrication and eliminate overload conditions |

| Cracked plates (fatigue) |  Crack from aperture towards edge of linkplate at 90º to line of pull. Note there is no linkplate distortion Crack from aperture towards edge of linkplate at 90º to line of pull. Note there is no linkplate distortion | Loading beyond chain’s dynamic capacity (above fatigue endurance limit) | Replace chain with leaf chain of larger dynamic capacity or eliminate high load condition or dynamic (impulse) overloading |

| Fractured plates (tension mode) |  Note material distortion Note material distortion | High overload | Replace leaf chain and correct cause of overload |

| Arc like cracked plates (stress corrosion) |  | Severe rusting or exposure to acidic or caustic medium, plus static pressure at press fit (between pin and pin linkplate). No cyclic stress is necessary for this phenomenon to occur. | Replace leaf chain and protect from hostile environment. |

| Enlarged holes |  | High overload | Replace leaf chain and correct cause of overload |

| Corrosion | Exposure to corrosive environment | Replace leaf chain and protect from hostile environment. | |

| Worn leaf chain anchor bolt connecting pin | Normal wear | Replace worn leaf chain components and always when fitting new leaf chains |