Lift chains are an extremely important part of the safe and efficient operation of a lift truck and unfortunately, they can be one of the most overlooked as well. It is up to the technician to properly inspect, maintain and if needed replace the lift chains safely. Below is a basic checklist of items to consider when inspecting lift chains. Remember that this is a general list, and you should always refer to the manufacturer specifications and manuals for inspection tolerances and procedures.

- Are lift chains properly lubricated with oil?

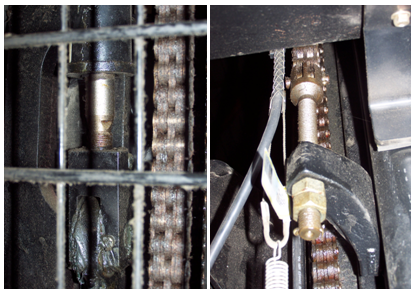

- Inspect for worn or turned chain pins

- Confirm that no chain link repair kits are installed

- Inspect chain anchors and pins for wear or damage or missing hardware

- Check for corrosion on links, pins and anchors

- Check for equal tension on chains with forks not touching floor

- Check for maximum 3% wear with a FB chain gauge Hyster #4044579 at a section of chain going over a chain roller

- Check for 5% maximum edge wear compared to new chain

- With truck on level surface and mast 90 degrees to floor, check for 1/4″ clearance under fork heels

- Check that carriage stop does not contact inner rail stop with mast fully raised

- Check that anchor nuts are fully engaged and lock nuts or cotter pins if required are present on anchor shaft

Please refer to the manual for the specific truck you are working on to ensure you are following the correct procedures.