Experience with these injectors

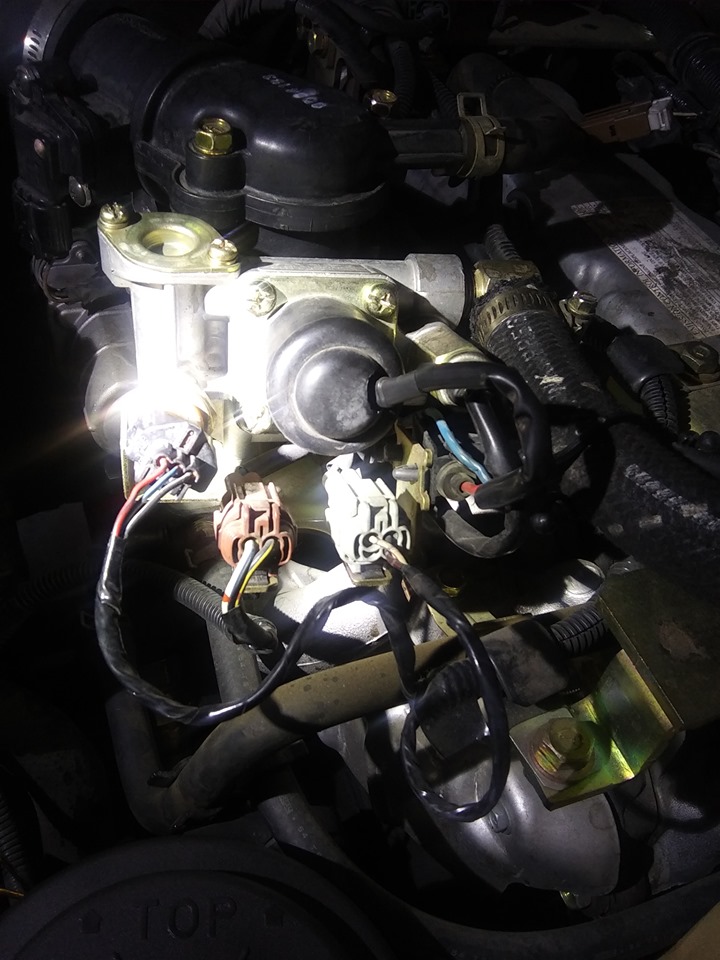

In cold temperatures (40F & Below) they intend to stick closed and the truck will not start. The primary cause is tar buildup on the injector nozzle. Sometime you can get lucky and remove the injector and clean the tip with choke and carb cleaner and it will solve the issue. A quick test for this is to use something soft like a screwdriver head and lightly tap the injector and occasionally it will come unstuck and the engine will start.

Another common problem is the o-ring on the nose of the injector gets torn or the o-ring goes missing and the engine will not start. Simply remove the injector and inspect the o-ring for damage and presence.

The most common problem with the injector is it has just gone bad and needs to be replaced. A good indicator of this is the 5A fuse on the injector harness is blown.

Error Code E35 and Inspection Procedures for LPG Injector (Cont’d)

1. Measure the resistance between the Terminals 1 and 2

Resistance: approximately 1 ohm

2. Remove the Fuse Cover and check if the Fuse is not blown

Make sure Terminals 1 and 2 are isolated from the Injector Body

without any short circuit

! CAUTION

• Do not apply any voltage to the Injector

Self-Diagnosis Results

When a malfunction occurs in the ECM input/output signal circuit, the malfunctioning circuit is recorded and displayed Also, the malfunction item that has occurred is displayed.

Display sample [Example: When there is a malfunction in the Mass Air Flow Sensor] Display DTC and the malfunction item in the alarm monitor screen.