| Fuel pressure gasoline [(kPa, bar, kg/cm2, psi)] | At idle: 353 kPa (3 .53 bar, 3 .6 kg/cm², 51 psi) |

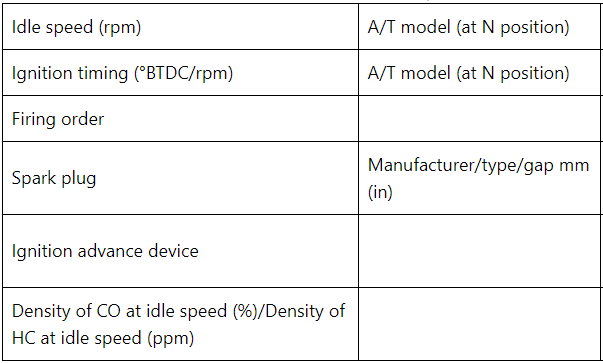

| Idle speed (rpm) | A/T model (at N position) | 700±50 |

| Ignition timing (°BTDC/rpm) | A/T model (at N position) | 0±2/700 |

| Firing order | 1-3-4-2 | |

| Spark plug | Manufacturer/type/gap mm (in) | NGK/FR2A-D/0 .8 – 0 .9 (0 .0031 – 0 .035) |

| Ignition advance device | Electrically controlled ignition advance | |

| Density of CO at idle speed (%)/Density of HC at idle speed (ppm) | 0 .1/50 or less |

- Turn Ignition Switch ON, and then make sure no malfunction is detected by self-diagnosis.

- Make sure the engine is free of Oil Pressure Pump loads and any electrical loads. Perform the inspection with the Shift Lever in the neutral or ‘N’ position.

- Warm up the Engine and Transmission to normal operating temperature

Idle Speed

With ECM Input/Output monitor. There is an OBD2 connector under the right side of dash under the cup holder on the Nissan, Mitsubishi, Caterpillar, & Unicarriers forklifts. Although, there is no adjustment for the idle speed.

Throttle Valve Closed Position Learning and Idle Air Volume Learning

When the electric throttle control actuator or ECM connector is removed, it is necessary for the ECM to learn the throttle valve closed position (throttle position sensor output with throttle valve fully closed) after reinstallation. Thus, throttle valve closed position learning is performed.

When the electric throttle control actuator or ECM is replaced, the minimum required idle air volume needs to be learned. Thus, throttle valve closed position learning and idle air volume learning are performed.

Idle air volume learning is necessary even when idle speed or ignition timing is outside the standard. Idle air volume learning is equivalent to manually adjusting the base idle speed adjustment via the conventional throttle adjusting screw of a carburetor or LPG mixer.

Operation Procedure for Throttle Valve Closed Position Learning

- Turn the Ignition Switch ON – OFF. And hold it for approximately 5 seconds after turning it OFF.) (At Least 5 Sec.)

- Make sure the Throttle Valve operates. (Check for operating sound.)

- Upon completion of the above, learning is complete.

Operation Procedure for Idle Air Volume Learning

Perform throttle valve closed position learning.

4. Fully warm up the Engine, Transmission, and lubricant. [Engine

coolant temperature: 70 to 90°C (158 to 194°F)] (80 degrees -84 degrees) MP

5. Set the Selector Lever to neutral or ‘N’ position. Make sure the Engine is free of electrical loads such as air conditioner, oil pressure pump and other electrical components. (Lights)

6. Perform “Idle Air Volume Learning” of “ECM Active Test”.

It will take approximately 20 seconds to complete the idle air volume learning. Do not turn OFF the Ignition Switch until completion.

•Complete “Idle Air Volume Learning” and make sure the idle speed and ignition timing are within the standard.

•Perform “Idle Air Volume Learning” again if values are outside the standard