Occasionally, a fault code or other problem will indicate an issue with the Power Distribution Module (PDM) or one of its circuits and it can be helpful if you know exactly how a PDM is constructed. If you suspect an internal issue or find a problem in your troubleshooting, the PDM can be removed from the truck and opened up to inspect the internals for problems or corrosion issues. You can drill out the 4 brass rivets in the corners of the PDM cover to open it up and later re-assemble the cover with ¼-20 bolts/nuts if you need to reinstall it.

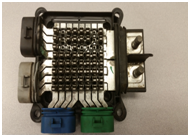

Have you ever seen the inside of a PDM? You may think there are circuit boards inside or transistors and such but in reality, the inside of a PDM is very simple. As the pictures below illustrate, the PDM internals are simply a series of interconnected bus bars that connect relay/fuse sockets, connector pins and the positive and negative bus bars of the truck.

If you look closely at the 2 pictures above with the covers removed, you will see this PDM has a pretty serious corrosion issue going on. The picture below is a close up of the CRP13 black plug bus bars taken with the plug housing removed, imagine the electrical gremlins this could cause in a truck.

It’s a bit hard to see but there is also corrosion between the upper/lower pins as well. This PDM was on a truck in a dry, heated warehouse and not a typically corrosive environment. It appears dust accumulated and then absorbed moisture and led to corrosion starting to form. CRP13 carries the outputs of the ignition, start and fuel run relays so imagine the problems this could induce in the unit. To troubleshoot the PDM use the laminated STL-1907 PDM pin out sheet from your Fortis/Veracitor class which is also available in the STL and Flow Charts folder in the Tech Image.

Now does this mean you crack open and inspect the PDM on every electrical issue you come across? No, but be aware of how corrosion in the PDM can lead to codes and intermittent or unexplained symptoms. If you find corrosion inside a PDM it should be replaced. Hyster offers a sealed PDM kit part #1697019 (Gram #PA00001) for typically corrosive applications (chemical, concrete, foundry etc.) Internal PDM issues can usually be diagnosed by simply using the pin out chart listed above and testing the connections and ensuring there is no continuity (shorts) between connection points that shouldn’t have any.